DRYTEC TROCKNER

Unser Anlagensortiment überzeugt durch eine Vielzahl an Lösungen für jeden Bedarf sowie eine erstklassige Trocknungsleistung, hohe Effizienz, Wartungsfreundlichkeit und optimale Zugänglichkeit. Eine Fülle optionaler Komponenten rundet das Angebot ab.

Trocken – können wir

Trocken können wir

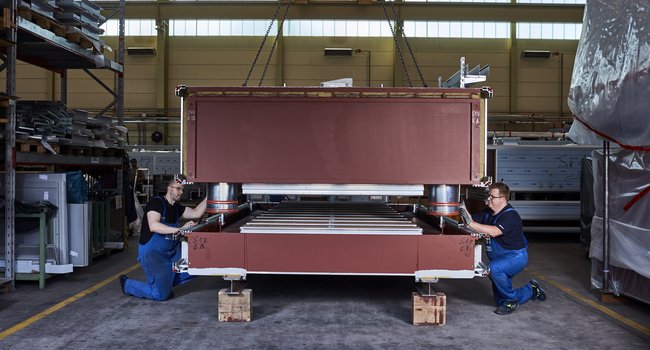

Schwebetrockner

DRYTEC Schwebetrockner sind die ideale Lösung, wenn im Rahmen von zweiseitigen Beschichtungen bahnförmiger Materialien die Führung des Materials durch Rollen oder Gurtsysteme nicht umsetzbar ist.

Rollentrockner

DRYTEC Rollentrockner sind mit einer ausgeklügelten Trocknungstechnologie für Dickbeschichtungen ausgestattet. Diese ist auch optimal für Beschichtungen, die zur Hautbildung neigen.

Gurtbandtrockner

DRYTEC Gurtbandtrockner überzeugen unter anderem durch eine Luftzufuhr von oben sowie dem Produkt angepasste Gurtbandtypen.

Labortrockner

- Trockner für Entwicklung, Kleinproduktion und Technika

- Einsatz aller DRYTEC Düsensysteme möglich

- sehr gutes Up-Scaling auf Großanlagen möglich

Sondertrockner

- geeignet für Hochtemperaturanwendungen bis 375°C

- Trocknung unter Inertgasatmosphäre

- Trockner entspricht FDA und GMP Richtlinien

Düsenbauarten

- hoher Wärmeübergang

- stabiler Substrattransport durch den Trockner

- gefertigt aus Alu-Strangpressprofilen für unübertroffene Genauigkeit und Leistung der Düsen